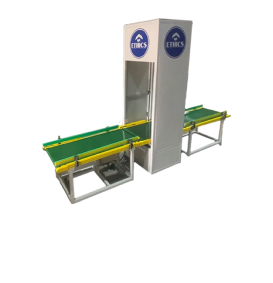

Dimensioning Weighing Scanning (DWS) Machine

With the ETHICS Infotech DWS (Dimensioning Weighing and Scanning) system, you can automatically measure and weigh items as they travel along conveyor systems, simplifying final-stage sorting and shipping processes.

The DWS system delivers exceptional logistics and inventory management efficiency while offering accurate measurements. Companies can utilize our DWS system to optimize storage space and plan deliveries strategically with precision using exact parcel measurements. This eliminates the risk of charging customers too much or too little due to inaccurate measurements, making for effortless inventory control and improved logistics operations.

ETHICS Infotech's Intelligent DWS System goes far beyond data collection to optimize shipping accuracy and improve customer delivery services. It provides companies with vital product details that increase profitability, efficiency, and customer satisfaction!

Features

Precision Measurement Capabilities

They make precise measurements of dimensions, such as weight, volume, and dimensions. They also ensure precision in the management of inventory and logistics processes.

Multi-Mode Functionality

It can accommodate various operational requirements, increasing the flexibility and effectiveness of multiple workflows.

Automated Sorting

Sorting processes can be automated to simplify operations, increase efficiency, and minimize human involvement.

Error Detection And Correction

Find and correct mistakes by automatism, which ensures data accuracy and minimizes disruptions to the operation.

Remote Monitoring And Control

Control and monitor operations remotely, which allows for real-time operation management and proactive decisions for improved efficiency.

Benefits Of DWS Machine

Increase Efficiency

DWS machines automate dimensioning, weighing, and scanning processes to reduce manual labor requirements while speeding up box processing times and increasing operational efficiencies.

Improve Accuracy

DWS machines employ cutting-edge sensors and technologies to precisely measure box dimensions, weight, and barcode information, leading to more effective inventory management, decreased shipment errors, and enhanced traceability.

Improve Warehouse Productivity

Increase warehouse productivity through their ability to quickly and accurately process large box volumes, helping organizations process orders more rapidly, manage sudden spikes in demand efficiently, and maximize throughput.

Cost Savings

DWS machines deliver long-term cost savings by cutting labor costs, minimizing errors, optimizing space usage, and increasing operational efficiencies - leading to greater profits and higher returns.

DWS Machines

ETHICS Infotech DWS For Efficient Shipping & Improved Customer Delivery Services!

A Dimension, Weighing, and Scanning (DWS) machine is an efficient system frequently utilized by logistics and shipping industries. Consisting of high-resolution cameras, load cells, and laser dimensioning sensors that accurately measure box dimensions and weight and capture barcode information all simultaneously, these automated machines increase workforce productivity at the warehouse by automating processes while providing real-time data that facilitates decision-making processes with more informed data analysis capabilities.

ETHICS Infotech’s DWS machine can help reduce mistakes and increase efficiency by automatizing processes. The data collection with our DWS machine can be more accurate than the manual method, thereby reducing the risks associated with weighting, dimensioning, and barcode read errors while accelerating operations faster and more efficiently, reducing labor costs associated with managing inventory.

With our DWS systems, reliability and accuracy are paramount. DWS machines are essential in modernizing warehouse operations, increasing the accuracy of shipping and inventory control operations, and strengthening overall supply chain effectiveness. Combining various functions into one system makes DWS machines an essential tool for businesses hoping to stay at the forefront of today’s ever-evolving logistical landscape.